About B.C. Jindal Group

The group was founded in 1952 by Shri B.C. Jindal. The USD 2.5 billion B.C. Jindal Group is among India's leading business houses. The Group, with a culturally diverse workforce across India, USA, and Europe, employs more than 10,000 people and has been offering a wide range of products and solutions since 1952. The Group by way of its innovative and sustainable presence in flexible packaging films, energy generation and downstream steel products play an important role in driving India’s economic growth. The Group strives for excellence by leveraging its strengths & capabilities including a successful track-record of executing capital-intensive & technically complex projects, including multiple acquisitions globally. Also, The Group has a strong social development focus aimed at empowering local communities residing around its plant locations.

JPFL Films Private Limited

JPFL Films Private Limited is a part of the USD 2.5 billion B.C. Jindal Group, which has been offering a wide range of products and solutions for more than 6 decades.

From being only a polyester yarn producer in 1985, JPFL diversified in 1996 into BOPET film production. In 2003, JPFL commenced production of BOPP film and metallised film. JPFL capabilities were strengthened by acquisition in November 2003 of Rexor S.A.S, in France, which produces metallised and coated films as well as tear tape, stamping foil, security thread and other high-value products.

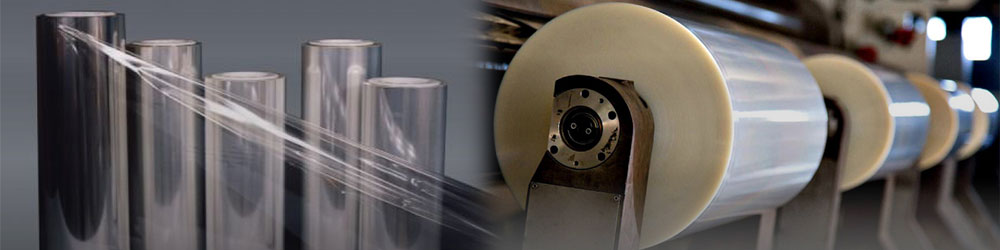

BOPP FILMS

We offer full range of BOPP Films from 7 to 70 microns which includes transparent Heat Sealable and Non Heat Sealable.

PET FILMS

We offer full range of PET Films from 7 to 350 microns which includes Chemical Coated, Opaque White, Matte.

METALLIZED FILMS

We are the Largest Manufacturer and Supplier of high quality Metallized Films.

CPP FILMS

We announced the commissioning of Its first CPP line at Nasik (Maharashtra) Plant.

THERMAL FILMS

We have recently installed a Extrusion Coating line for BOPP & BOPET based Thermal Lamination Films.

COATED FILMS

We offer wide range of speciality Coated Films like PVDC, Acrylic, Siliconised, AlOx, Ink Receptive, Digital Printable.

NON TEARABLE PAPER (NTR)

We offer NTR films in Matte and Glossy finish for diverse applications like Photo Albums, Certificate.

CAPACITOR, BOPA & MASTERBATCHES FILMS

At JPFL, we conduct our business following the Guiding Principles and endeavour to comply with all applicable legal and internal Environmental, Health, and Safety requirements. Our focus on operational excellence enables continual improvement of our EHS systems, products and activities. These initiatives allow us to better conserve energy and natural resources, prevent pollution and protect the health, safety of our employees and the public.

Our Zero-Incident Policy Safety of the environment, people and communities is important to us. We promise to conduct all aspects of our business to safeguard our employees, the communities we live and work in, and the environment.

BRC Certificate

BRC Certificate  ISO 9001 Certificate

ISO 9001 Certificate  ISO 9001 Certificate

ISO 9001 Certificate

Jindal Poly Films Limited

Since its entry into Flexible Film Manufacturing business in 1996, Jindal Poly Films Ltd. (JPFL) has turned into an over USD 500 million turnover company with 2500+ workforce focusing on trust, value for customers, quality innovation and customer satisfaction. The company stands out in the flexible packaging industry in India as a one-stop-shop film solution provider across all segments. JPFL commands the highest market share in the Country and its Nashik Plant, owned by one of its subsidiary JPFL Films Private Limited is the world’s largest single location facility for the manufacturing of flexible packaging films.

Mrs. Sonal Agarwal

Non - Executive Director (Independent)

Mr. Rathi Binod Pal

Non - Executive Director

Mr. Sanjeev Aggarwal

Non - Executive Director

Mr. Vijender Kumar Singhal

Whole Time Director & CFO

Mr. Sanjeev Saxena

Non - Executive Director

Mr. Prakash Matai

Non - Executive Director

Jindal (India) Limited

Jindal (India) Limited derives its strength from the vision of Late Shri Bhavi Chand Jindal, founder of the B.C. Jindal Group, a visionary leader who, shortly after India's independence, embarked on the journey of establishing Jindal (India). His goal was for the company to play a crucial role in making India self-reliant in the steel industry

Jindal (India) Limited, established in 1952, has grown from its origins in pipe manufacturing in Kolkata to become one of the leading players in India’s downstream steel industry. Known for its diverse product portfolio, it offers a comprehensive range of products across three major divisions: Sheets, Pipes, and Aluminum foil. The company’s advanced capabilities include state-of-the-art color coating, galvanizing, and galvalume technologies. It is also one of the few Indian manufacturers in the infrastructure sector with API monogram certification, enabling the company to supply high-quality line pipes, casing, and tubing to the oil and gas industry.

Jindal (India) Limited proudly stands at the forefront of India's steel industry, with over 70 years of unwavering commitment to excellence. As a leading producer of coated steel products including galvanized, galvalume, and pre-painted galvalume products, as well as corrugated sheets and coils - the company has earned the trust of customers worldwide, spanning from Latin America to the Far East.

A key player in the ERW galvanized and black pipe segments, Jindal (India) Limited offers a comprehensive range of coated API pipes for the oil and gas sector, as well as structural pipes and pipes for fluids. With sizes ranging from 1/2" to 20" and the ability to meet stringent requirements up to API X70 grade, the company effectively serves critical industries.

Additionally, Jindal (India) Limited is a pioneer in the Indian aluminum foil industry, producing ultra-light gauge foils that meet the highest industry standards.

The Board of Jindal (India) Limited comprises of the experienced people from the manufacturing business and assisted by a team of qualified and experienced people.The Company has the following Directors and Key Managerial Personnel (KMP):

Mr. Binod Kumar Singh

Whole Time Director

Mr. Pramod Kumar

Director

Mr. Sanjeev Aggarwal

Director

Mr. Deepak Agarwal

Director

Ms. Sarmistha Chowdhury

Director

Ms. Sudhanya Sengupta

Company Secretary

Mr. Deepak Garg

Chief Financial Officer

Jindal India Power Limited

The group diversified into power generation sector in the year 2006. Jindal India Power Limited (JIPL) has set up a 1200 MW capacity coal based Thermal Power Plant (TPP) in village Derang, Angul District of Odisha State. JIPL has two units each having 600 MW capacity and is in operation since 2015. The power plant is in proximity to the coal mines in Talchar coalfields of MCL. Water requirement of plant is met from Brahmani River from the upstream of Samal barrage at a distance of 14KM from the plant.

JIPL is aimed at building an achievement-oriented organization with employee friendly policies. It is committed to run its business in an eco-friendly manner with special focus on environment, health and safety.

The power generated from the power plant is supplied to various utilities across India under power purchase agreements.

Plant Location:

The plant is located at Village Derang, District Angul in the state of Odisha. The site is 4 KM away from NH-53. Bhubaneshwar is the nearest Airport which is about 180KM from plant location and nearest Railway Station is Talcher Road which is about 45KM from the plant. Paradip, the nearest port is about 230KM.

Plant is spread over an area of 1100 Acres land. The plant is strategically located due to its proximity to coal mines, water source and connectivity with PGCIL’s Angul pooling station through a double circuit 400KV transmission line.

Power Plant technology and Major OEMs

JIPL always believed in quality and hence all equipment are sourced from reputed suppliers with the latest state-of-the-art technology. Following are the list of major suppliers and contractors:

- BTG Package - EPC by M/s Bharat Heavy Electricals Ltd (BHEL)

- Cooling Towers by M/s Paharpur Cooling Towers

- Ash handling System by M/s Macawber Beekay

- Coal Handling System by M/s Tecpro

- CW System by M/s KBL

- Water Treatment System by M/s Ion Exchange

- Switchyard by M/s Siemens

- Transmission line by M/s Gammon India

- Major civil works by M/s Shapoorji & Pallonji.

Coal & Water:

The annual coal requirement of the plant is around 7.0 million MT. Entire coal is sourced from MCL through linkage and other modes of allocation.

The water requirement for the plant is 25 Cusec and is drawn from the Samal Barrage on Brahmani River which is located at 14KM from the plant.

Power Supply:

The power is evacuated through a 77 KM long dedicated 400KV double circuit transmission line connected to PGCIL’s Angul Pooling Station. The power is supplied to various discoms and other consumers including Kerala, Bihar, Gujarat, Indian Railways etc.

Mr. D. Vijayabhaskar Reddy

Whole Time Director and CEO

Mr. Sunil Kumar Aggarwal

Whole Time Director

Mr. Sandip Goswami

Whole Time Director

Ms. Kaminee Girdhar

Director

Mr. Krishan Kumar Sabharwal

Non Executive Director (Independent)

Mr. Suresh Chander Sharma

Non Executive Director (Independent)

Jindal India Renewable Energy Limited

Jindal India Renewable Energy Limited, a part of B.C. Jindal Group is committed to renewable energy generation. Building on our legacy in power industry, we aim to create a carbon-free footprint and foster a community of professionals dedicated to shaping the future of energy in India and globally.

Focus Areas

SOLAR

SOLAR  WIND

WIND  HYBIRD

HYBIRD  STORAGE

STORAGE  SOLAR CELL & MODULE MANUFACTURING

SOLAR CELL & MODULE MANUFACTURING

SOLAR

Solar energy uses sunlight to generate renewable power. Solar panels convert sunlight into electricity through the photovoltaic effect. More light exposure increases their electricity production. The sun's photon energy can be harnessed to power the planet.

WIND

Wind energy captures the power of the wind to generate renewable electricity. Onshore and offshore wind farms generate power by spinning wind turbine blades. These turbines convert the kinetic energy of the spinning blades into electric energy, providing a sustainable energy source.

HYBRID

Hybrid renewable energy systems generate electricity from multiple sources, like wind and solar, sharing a single connection point. This system optimizes the use of renewable sources, ensuring more sustainable energy production with minimal waste.

STORAGE

Energy Storage Systems store electrical energy in batteries for later use. They manage the variability of renewable sources like solar and wind. Stored energy is used during peak hours. These systems help maintain grid stability.

SOLAR CELL & MODULE MANUFACTURING

A PV (or solar) cell is a semiconductor device that traps solar energy and converts into electricity. A PV module (or panel) comprises an assemblage of solar cells in a sealed, weather-proof packaging and is a fundamental building block of photovoltaic (PV) systems.